Whether you plan to shelter your RV, house your livestock or front your business, building any type of pole barn is a big investment in terms of your money, time and personal energy, so you want you make the right decisions from the very beginning. It starts with choosing your builder; but with so many options in the market, how do you know you’re making a wise choice? We visited with two Lester Building Systems representatives – Territory Manager Joe Bjelland and Justin Sobaski, vice president of Eastern Iowa Builders – who shared their wisdom and described, “Why choose Lester Buildings?”.

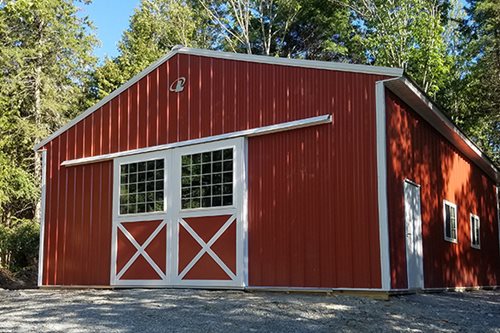

Lester Buildings Project # 601893

REASON #1 – An engineered pole barn is stronger

Oftentimes, the only engineered component in a post frame building is the truss. However, trusses are dependent on the strength of the rest of the building for support and bracing.

“A building is only as strong as its weakest link,” explained Bjelland. “If you have a truss with a certain loading specification and put it on a column that doesn’t meet the truss specifications, then the truss is going to be only as strong as the weaker column.” In practical terms, this means that the chance of your structure failing during a heavy snow, for example, are greater.

Lester buildings, on the other hand, are engineered to withstand wind and snow loads for the county in which they’re located. “Every county has designated snow load requirements dictated by international building code,” said Sobaski. “As you go farther north, snow loads get heavier, obviously. Lester engineers each building to meet or exceed those local snow load codes. The same is true for wind loads.”

The exposure category into which your pole barn fits is another factor Lester takes into account when it comes to design loads. Whether your structure is situated on top of a hill and catches a lot of wind, is nestled on a wooded lot or sited in a heavily populated area with buildings all around, every component of a Lester building is designed to meet those conditions and work together as a complete building system, resulting in much stronger construction.

Lester Buildings Project # 219391

REASON #2 – We’ll work with you to understand and meet design loads

As noted above, wind and snow loads are critical concepts to factor into the design of your new building. As a buyer, the challenge for you can be in understanding what your local loads are, and which terms are being quoted in proposals you receive from builders. Ground snow load, for example, is not the same as roof snow load, and different builders may quote on one or the other but not clarify which they’re referring to.

Your Lester representative, however, can meet with you at your building site to discuss applicable local codes. While onsite, your Lester rep also can see where the building will be located on your lot or land, where to site the building pad, where to locate doors, etc. Taken together, these site and load specifications will have a great impact on the overall design and ultimate performance of your building.

You’ll also have peace of mind knowing that you’re working with local professionals, from initial planning to completing the final punch list. “That means you’re working with someone who knows and understand the local building codes, knows and has connections with subcontractors like concrete layers, insulators, electricians and plumbers,” Sobaski said. “We really leverage our relationships with subcontractors. It’s a better, more professional way to build.”

Furthermore, “When you work with a local Lester representative, you’ll have the benefit of their experience, what’s worked well and what hasn’t,” Bjelland said. “We’ve been around a long time and have designed a lot of buildings.”

In fact, since the company was founded in 1947, Lester has built more than 170,000 buildings across 35 States. The company also takes great pride in employing generations of hard-working local residents, further strengthening our institutional knowledge of building best practices.

Lester Buildings Project # 605186

REASON #3 – Quality components

As important as an engineered pole barn is, a complete building system is still only as good as the quality of its individual parts. The following list exemplifies Lester Building’s insistence in using only the finest quality components:

Lumber

Trusses are engineered, prefabricated, and manufactured by order using MSR southern yellow pine or Douglas fir lumber as specified by Lester engineering to meet your building’s unique requirements. MSR lumber is evaluated by mechanical stress-rating equipment to ensure it meets certain requirements. “You need to know exactly how strong that lumber is because you’re designing the truss to hold up a specific amount of weight,” Sobaski said. Most building suppliers also use engineered truss grade lumber.

One thing that sets Lester buildings apart is the double press process that is used to manufacture the truss by first pre-press, which applies 100 tons of force, then the truss is sent through a roller press. The press engages the teeth of the truss plates into the wood, so it is properly set. Other manufacturers just use one roller to press down, which on larger trusses can distort the plates prior to getting them properly pressed. See how Lester buildings are manufactured.

Lester also uses a third-party inspection agency, Truss Plate Institute (TPI), that conducts random checks to ensure the quality of Lester’s manufactured trusses. This ensures ongoing quality control.

Other building suppliers also typically use “human graded” lumber in the rest of the building’s framing. Think of visiting your local big box home improvement store and eye balling planks of wood – no peeking inside each piece to see areas of weakness. What sets Lester buildings apart is the same MSR lumber that is used in the truss is also used and engineered for the entire framing system.

Steel

Lester uses a 28-gauge roof and wall panel as opposed to standard 29-gauge. An option for a 26-gauge panel is also available. All layers of the steel panels, from steel coil to paint and design, are specified and tested in house. What is more, the company roll-forms the panels and trim in house. Watch how roll-forming is done.

Fasteners and connections

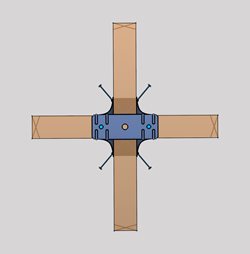

If you’ve read this far, you’ll also want to know that, in a typical post-frame building, 2x4 roof purlins are installed on edge, on the top of the roof truss. Each purlin is then nailed with one ring shank nail to fasten it to the truss.

Overhead of purlin to top of single-ply truss

|

Purlin to top of single-ply truss

|

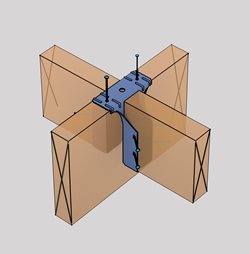

In contrast, “We install a metal saddle hanger over the top of the trusses and nest the purlins in the metal hangers flush with the top cord of the truss,” Sobaski said. “Then, at each truss to purlin connection, we use eight fasteners, not just one. The flush connection is much stronger than a 2x4 on top of the trusses.”

“We also use a nested truss connection,” he continued. “The middle ply of our column is kept lower and the truss is nested in between, as opposed to being nailed to the side of the column. A nested truss connection is a stronger connection.” See the building details of a Lester Building.

Lester engineers and manufactures each column location to the specific design requirements. For example, a column at a large door opening carrying the load from a large door header needs to be designed differently than a column that is on an endwall. Lester engineers each and every column in your building to those specific design requirements. Lester columns are also finger-jointed at all splices, making the joint stronger than the board itself.

Lester Buildings Project # 304188

REASON #4 – Lester’s pole barn warranty is the industry’s best

When examining a pole barn’s warranty, the most important thing to ask is, “How many of the components does the building company manufacture and warranty itself?” When a company purchases each component from a different supplier, the warranty is not nearly as effective as if the building company manufactures its own components. Sobaski tells his clients:

“If a builder purchases steel panels from company XYZ, and you have a warranty issue with your steel down the road, then not only does the company that you purchased the building from have to still be in business, but the steel company also has to be in business. The same is true for columns, trusses and every other warranted component on or in the building.”

“Lester manufactures its own trusses and columns. They also roll form their own steel. Every main component of your building is manufactured and warrantied by Lester, which gives you the best warranty protection in the industry.”

Bjelland added, “We can offer a lifetime structural warranty on all of our buildings because of the historical data on how our fully-engineered buildings have performed over the span of our company’s history.”

Just what does a lifetime pole barn warranty translate into in practical terms? For individual customers, a Lester building is warranted for as long they own the building. “If you build it when you’re 20 years old and you own it until you reach 100, the warranty would be 80 years,” Bjelleand said. For non-natural persons, such as businesses and corporations, the Lester building is warranted for 50 years. “Most other builders can’t do this.”

Lester Buildings Project # 270582

REASON #5 – The customer experience

We understand that building a pole barn is a significant investment, which is why it is important to us that we provide a professional, collaborative planning experience from concept to completion. You can count on Lester to guide you through the pricing, planning and construction of your building. Together we will collaborate to bring your dream building to life.

“We made contact with several different companies that built – some companies followed up with us, others did not. When we contacted Lester, they were the fastest to meet with us and the most thorough with the process from beginning to end,” said the Peterson Family, who are customers of Lester.

To sum it all up

Your custom dream pole barn is waiting for you. But before you commit your valuable time and money, you need to make sure you’re headed in the right direction. To learn more tips before buying a pole barn, download our Evaluating Your Building Supplier Guide and take the worry out of finding the right building supplier.